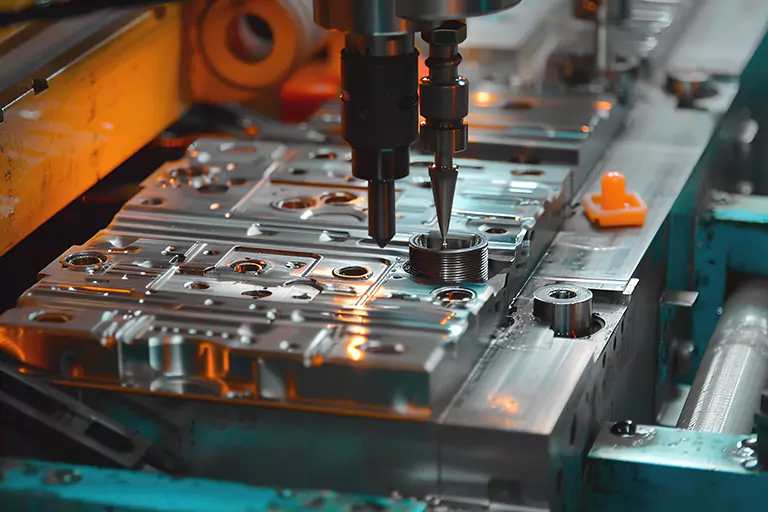

The choice of thermoform molds is crucial for manufacturers looking to optimize their production processes. High-quality thermoform molds directly impact the efficiency, cost, and overall quality of the final product. By selecting the right mold, businesses can ensure better product consistency and reduce material waste. Mikformen offers a wide range of molds designed for various applications, including PET packaging, PET cases and polypropylene cases.

Key Factors in Thermoform Mold Selection

When choosing a thermoform mold, the type of material being used, the desired thickness of the product, and the complexity of the design should be considered. The right mold not only enhances productivity but also contributes to sustainability efforts by minimizing scrap and optimizing material usage. As the demand for efficient and eco-friendly packaging grows, understanding the importance of mold selection becomes essential for businesses aiming to stay competitive in the packaging industry.

Contact us for more details and information about Mikformen Thermoforming Machines.